Man vs machine – who schedules staff better?

by Rotageek on 25 September 2020

It’s become one of the more tired tropes in technology, an almost ‘age old’ question in what is still a relatively new field: are artificial intelligence, machine learning and algorithms ‘better’ than the natural intuition found in humans? The debate rages on across the board and, in cases like the Harvard Business Review’s test around hiring practices, sometimes instincts outweigh algorithms. In short, sometimes machines don’t know best.

So, what’s the case in the world of staff scheduling? If faced with the task of creating compliant schedules for an organization – say, a selection of high street retail stores – which comes out top? Let’s explore that in our rundown of ‘man vs. machine’ in the world of staff scheduling.

Man vs machine: which is better at staff schedules?

Why is scheduling hard?

Most businesses face the challenge of creating legally compliant schedules that can staff to meet varying demand. In retail or food service, this can be because customer demand patterns vary throughout the day, week, and year. In healthcare, this is because many competing legal requirements and time-off requests can make staffing every shift particularly challenging.

Scheduling employees efficiently is one of the canonical hard problems in computer science. These problems are described as NP-hard, because of how quickly the number of possible solutions grows as you make the problem only slightly bigger.

As an example, imagine a business that has five shifts that need to be worked in the week and two employees that can work those shifts. There are 32 (2^4) possible schedules that could be created. If you simply double both the number of shifts and number of employees, there are now more than one million (4^10) possible combinations of shifts.

The problem becomes only more complex as shifts no longer have fixed times or workers can work different tasks over the course of their shift. These changes allow for schedules that better match customer demand, but greatly increase complexity. The number of possible staff schedules quickly becomes so large that it is impossible to search or think about all of them.

How do managers schedule?

Scheduling isn’t a new problem and at most businesses, schedules are still made by a manager. So, how do managers think about possible schedules and condense the problem into something more manageable?

At Rotageek, we’ve seen a variety of approaches used to reduce the number of possible solutions, but a general approach might look something like:

- Begin by reducing schedule complexity by limiting shift start times, shift lengths, and the number of different types of work someone can do in a shift

- Fill the hardest to fill positions

- Make sure you have the minimum required staff (keyholder, till, etc.) to keep the store open in all time slots

- Identify periods of high customer demand and staff more people to work during that time

The result of this is a pattern of shifts that need to be worked in a week. Then, for a particular week, a manager will assign these shifts to workers, taking into account leave, contractual and legal requirements.

This approach has three downsides. First, it can rule out solutions that better match customer demand. By limiting the flexibility of shifts, many solutions that would more efficiently match demand are no longer possible.

Second, the list of shifts to be worked don’t adjust when the amount of staff available to work them changes. For example, if there is a one hour demand peak in the middle of the day, a manager might have two workers overlap but work five hours on either side of the peak. If only one worker is available, the best solution would not be to leave one of those six hour shifts unfilled but instead shift the remaining shift to better fill demand.

Third, as customer demand changes, the pattern of shifts will be outdated and inefficient. Rethinking the pattern of shifts requires significant investment and so managers don’t do it regularly. As a result, schedules get worse and worse until the manager starts the process again to come up with a new pattern for shifts.

How does a computer schedule?

When a computer thinks about scheduling, it often does it in a way that is very different from human managers. For a manager, generating a schedule is a laborious process, so only a few possible candidates are ever considered. As a result, a lot of thinking goes into the placement of every shift. In contrast, a computer is able to generate and evaluate millions of possible schedules every minute, so instead of thinking hard about the placement of each shift, it focuses on trying out as many good options as it can.

Optimisation algorithms generally break their work into two steps that are repeated until a good schedule is found:

- Generate a possible schedule

- Decide if the schedule is good or bad

Deciding whether a schedule is good or bad is just a function of the rules and requirements that are unique to each business. All of the hard work lies in trying to find a good way to create possible schedules. As described above, there can be billions of possible solutions, so it’s just not feasible to search all of them.

The hardest decision is whether to spend most of your time searching in the neighbourhood of ‘already found’ good schedules or explore schedules that are nothing like what you have searched before. This is called the exploration-exploitation trade-off, and striking the right balance is one of the most important decisions in an optimization algorithm.

Who wins the head to head?

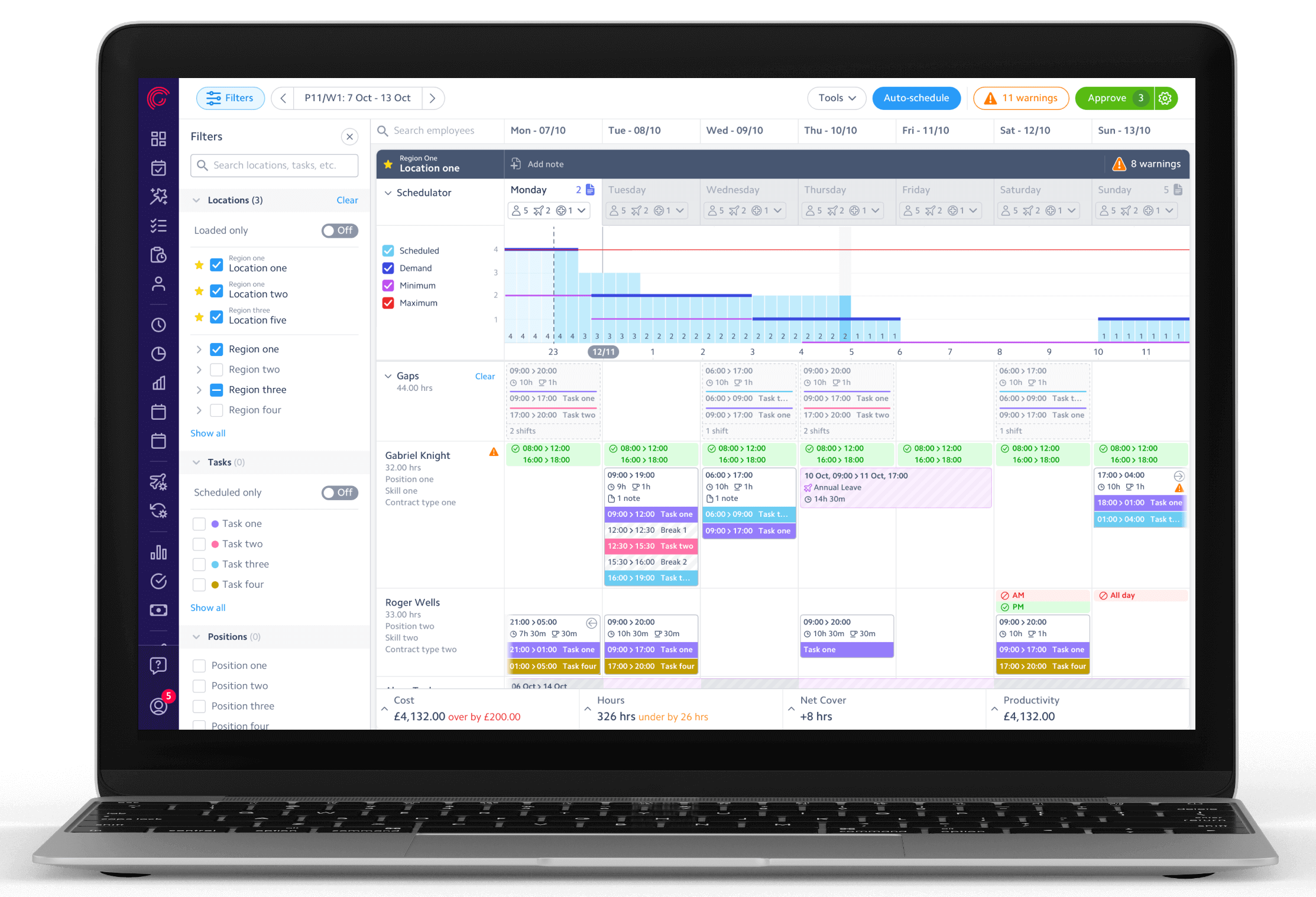

Rotageek’s Autoscheduler is a fully-configurable schedule optimisation tool. Customers can specify all of their business rules and provide relative weightings. The Autoscheduler will then return a schedule that satisfies as many of these rules as possible, obeying the provided relative weightings when rules come into conflict and one must be broken.

Under the hood, the Autoscheduler relies on a number of different optimisation algorithms and uses one or more of them depending on the exact specifications of the problem. This allows it to efficiently search many possible solutions to find a good schedule.

So, the golden question remains: After all is said and done, who truly wins in the battle of the schedules? When Autoscheduler-created schedules are compared to manager-created schedules, we find that they are about 14% better at matching customer arrival patterns, forecasting and creating the perfect labour match, plus have have fewer legal and business requirement violations. The improved efficiencies can be realised as cost savings or reinvested to provide a better customer experience; all great news for business - particularly in the retail sector - under pressure to perform.

A manager’s intuition is essential for identifying scheduling norms and making last minute adjustments as people go sick, but generally, their time is better invested in the tasks that they excel at - engaging employees, improving customer experience and running effective teams.

- Quick links

- Log In

- Book a Demo

- Help Centre

- Products

- Digital Scheduling

- Autoscheduling

- Forecasting

- Company

- Our Story

- Careers

- Blog

- Privacy Policy